We use cookies to offer you the best experience on our site. You can find out more about the cookies we use or disable them in the settings. Cookie settings

Introduction

Why aren't there more Waste Heat recovery projects in industry?

Although many heat exchanger technologies are available on market, most projects dedicated to Waste heat recovery in small and medium industries do not come into application. This situation leads to a status quo which is said to be due to:

- Too long payback time;

- The lack of technologies able to comply with all the needs related heat recovery from fumes: performance, low pressure drops, thermal compliance, corrosion resistance;

- The many constraints related to retrofitting installation: space available, passive supporting structure (civil engineering), maintenance, …;

- The lack of information about possible and available valorizations of the recovered thermal power.

Finally, and despite the fact that heat exchangers are critical to many industrial processes, the technologies available on market are poorly suited for waste heat recovery applications on industrial fumes and exhaust gas with temperature higher than 150°C.

This is the problem we want to fix! And this is exactly why we have developed the GAP heat exchangers.

Type of wasted heat

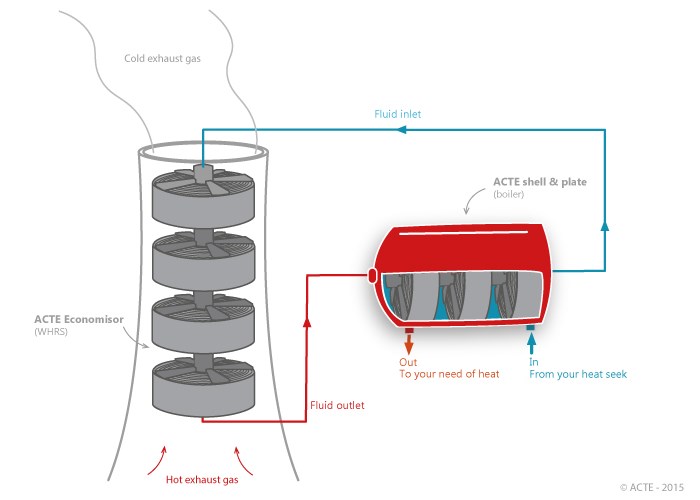

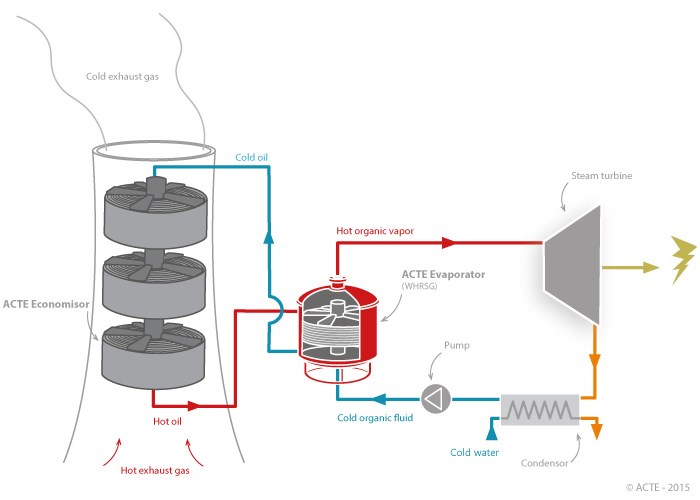

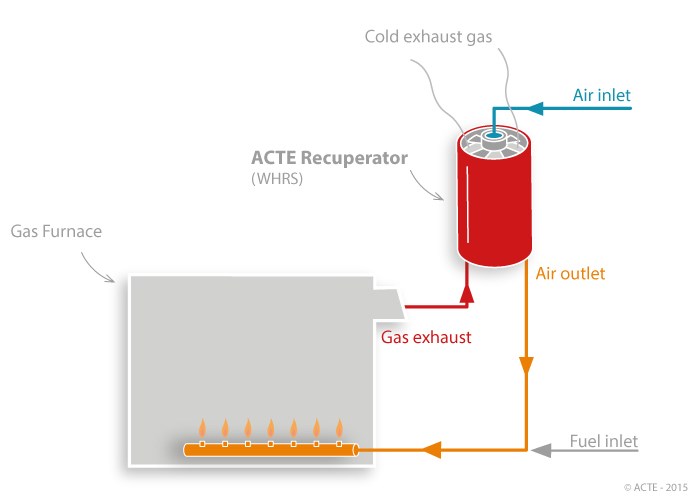

ACTE's GAP heat exchangers can be used as "chimney heat exchanger" and allow you:

- to recover heat from hot exhaust gas coming from your furnace,

- to recover heat from your process and valorize it in a drying system,

- to warm water in a building heating system or in a cleaning/sterilization system by producing hot air, hot water, hot oil or low pressure steam.

The use of heat exchange primary surfaces linked to an annular shape makes the economisers, heat recovery boiler or cooling tower particularly compact and allows you to minimise the installation footprint and the supporting civil engineering structure, and therefore to obtain the best return on investment.

The modular components also enable you to benefit from a custom-built solution that is adapted to your needs.

An alternative to standard heat exchangers

The ACTE GAP heat exchangers can be used in the oil & gas industry where classic “Shell & Tube” heat exchangers were used in the past. Indeed, the “Shell & Plates” ACTE heat exchangers will bring you the following benefits:

- Low pressure losses

- Low weight

- Compactness

- High performances

- High thermal stress resistance

Our strong R&D and Engineering team can also help you in case of special requirements such as an automatic cleaning system study of the heat exchanger, fan sizing and integration, special process interfacing, non-standard thermal fluid use, ...

References

ACTE is helping customers from all around the world for 20 years. We are active on each continent.